I. Introduction: The Power Problem in Precision Agriculture

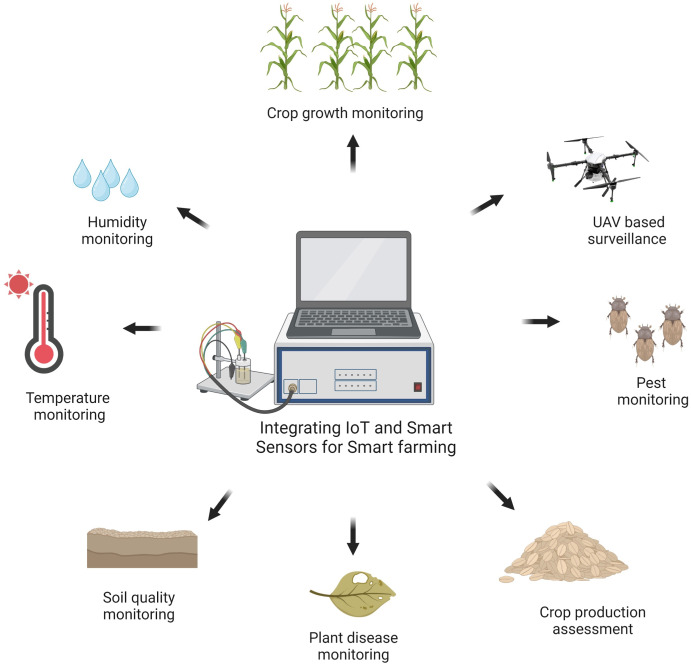

The agricultural sector stands on the cusp of a technological revolution, driven by the principles of Precision Agriculture (PA). This movement promises to optimize resource use, maximize yields, and minimize environmental impact through the deployment of sophisticated sensor networks. Imagine a farm where every square meter of soil is monitored in real-time, providing granular data on moisture levels, nutrient uptake, pH balance, and even early signs of pest infestation. This is the vision of the Internet of Things (IoT) in farming, a future where data-driven decisions replace guesswork.

However, the path to this hyper-efficient, data-rich farm is riddled with a single, persistent obstacle: power.

Modern smart farms require thousands of distributed sensors, often placed in remote, harsh, and inaccessible locations. Each sensor needs a reliable, continuous, and sustainable power source. The current solutions are fundamentally flawed for this scale of deployment.

The Limitations of Traditional Power Sources in the Field:

- Batteries: While simple to deploy, batteries are a logistical and environmental nightmare. They require constant replacement, leading to high labor costs, system downtime, and the disposal of toxic waste. For a large-scale farm with thousands of sensors, the maintenance burden alone can negate the efficiency gains of the PA system.

- Solar Panels: Solar power is clean and renewable, but it is inherently intermittent. It requires bulky, expensive battery backups to provide power at night or on cloudy days. Furthermore, solar panels are vulnerable to dust, dirt, and physical damage in a farming environment, requiring frequent cleaning and maintenance. Their above-ground presence also interferes with farm machinery and operations.

- Wired Power: Running power lines across vast fields is prohibitively expensive, impractical, and often impossible, especially in remote or difficult terrain.

This power bottleneck has been the single greatest inhibitor to the widespread adoption of true, high-density sensor networks. Farmers are forced to choose between low-density, less effective monitoring or high-maintenance, costly power solutions.

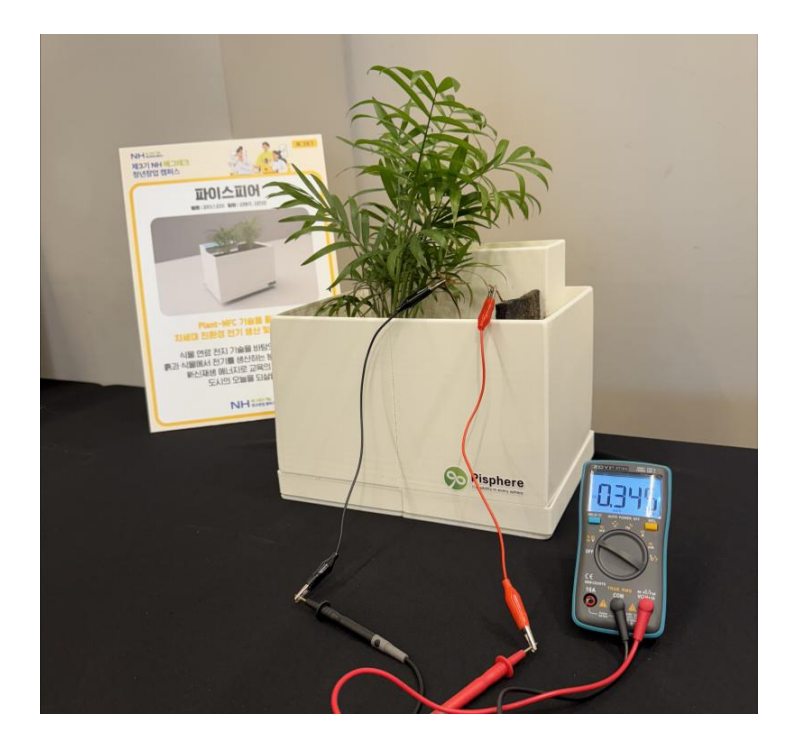

This is where Pisphere enters the agricultural landscape, offering a paradigm shift. By harnessing the natural bio-electricity generated by plants and soil microbes, Pisphere provides a completely self-sustaining, embedded, and maintenance-free power source perfectly suited for the demands of precision agriculture. It is the technology that finally allows the farm to become truly “unplugged.”

II. Pisphere Explained: The Plant-MFC Engine

To understand Pisphere’s revolutionary potential, one must first grasp the elegant simplicity of its core technology: the Plant-Microbial Fuel Cell (Plant-MFC). This is not a solar panel, nor is it a battery; it is a biological generator that turns the natural processes of plant growth and soil ecology into a continuous stream of electricity.

The Science of Bio-Electricity

The process begins with the plant itself. As a plant performs photosynthesis, it produces sugars and other organic compounds. A significant portion of these compounds—up to 70% in some species—is not used for growth but is instead secreted through the roots into the surrounding soil. This process is known as rhizodeposition.

The soil is a complex ecosystem teeming with microorganisms. These microbes consume the organic compounds released by the plant roots. In a typical soil environment, the microbes use oxygen to break down these compounds, a process called aerobic respiration. However, the Pisphere system creates an anoxic (oxygen-deprived) environment around a submerged anode.

In this anoxic zone, certain types of bacteria, known as exoelectrogens, are forced to use an external electron acceptor to complete their metabolic process. The Pisphere anode serves as this external acceptor. As the exoelectrogens consume the plant’s organic waste, they effectively “breathe” by transferring electrons directly onto the anode. These electrons then travel through an external circuit—the sensor network—to a cathode, generating a continuous electrical current.

The Pisphere Advantage: Enhanced Electron Transfer

Pisphere’s innovation lies in its optimization of this natural process. The system utilizes specific, highly efficient exoelectrogenic bacteria, notably Shewanella oneidensis MR-1. This microbe is renowned for its ability to transfer electrons efficiently to solid surfaces, significantly boosting the power output of the Plant-MFC.

Furthermore, the Pisphere device is designed to be embedded and buried directly into the soil, maximizing contact with the root system and the microbial community while remaining completely out of the way of farming operations.

Key Technical Specifications for Agricultural Use:

| Feature | Pisphere Plant-MFC System | Benefit for Farmers |

|---|---|---|

| Power Source | Plant root exudates and soil microbes | Self-sustaining, requires no external fuel input. |

| Power Output | 250-280 kWh per 10m² annually (optimized) | Sufficient to power multiple low-power sensors and transmitters. |

| Operation | 24 hours a day, 7 days a week | Reliable power, day and night, regardless of weather. |

| Maintenance Cost | $10-15 USD per year (estimated) | Extremely low operational expenditure compared to batteries or solar. |

| Environmental Impact | Zero waste, carbon neutral | Meets growing demands for sustainable and ESG-compliant farming. |

| Physical Profile | Embedded/Buried | Does not interfere with machinery or aesthetics. |

This technology fundamentally changes the economic equation for sensor deployment. By eliminating the costs associated with battery replacement, solar panel maintenance, and intermittent power, Pisphere makes high-density, real-time monitoring economically viable for farms of any size.

III. The Practical Application: Powering the Sensor Network

The true value of Pisphere is realized when it is integrated into the operational fabric of a modern farm. Its low, continuous power output is perfectly matched to the requirements of the most critical components of a precision agriculture system: the Low-Power Wide-Area Network (LPWAN) sensor nodes.

The Perfect Match: Pisphere and LPWAN

LPWAN technologies, such as LoRaWAN and NB-IoT, are designed to transmit small packets of data over long distances while consuming minimal power. A typical sensor node in a LoRaWAN network might require only a few milliwatts of power for its daily operation, with short bursts of higher power for data transmission.

Pisphere’s continuous, low-voltage output is ideal for trickle-charging a small capacitor or buffer battery within the sensor node. This ensures that the node always has enough stored energy for its periodic data transmission cycle, even if the instantaneous power draw exceeds the MFC’s output.

Specific Sensor Applications in Farming:

- Soil Moisture Probes: These are the most common and critical sensors. Pisphere can power probes that measure volumetric water content, allowing farmers to implement Variable Rate Irrigation (VRI). This means watering only where and when necessary, leading to massive water savings and preventing crop stress.

- Nutrient and pH Meters: Real-time monitoring of soil pH and key nutrients (Nitrogen, Phosphorus, Potassium) is essential for optimizing fertilizer application. Pisphere enables the continuous operation of these chemical sensors, providing data that allows for micro-dosing of fertilizers, reducing runoff and environmental pollution.

- Microclimate Monitoring: Temperature and humidity sensors placed at various heights and locations provide a detailed map of the farm’s microclimates. This data is crucial for predicting frost events, optimizing fungicide application, and managing heat stress in livestock or crops.

- Pest and Disease Monitoring: Low-power cameras or acoustic sensors can be powered by Pisphere to monitor insect populations or detect the early signs of plant disease, enabling targeted, minimal-intervention pest control.

Installation and Deployment: A Step-by-Step Guide

The deployment of a Pisphere-powered sensor network is surprisingly straightforward, requiring minimal disruption to the field.

Step 1: Site Assessment and Planning:

- Identify the zones requiring the highest density of monitoring (e.g., areas with variable soil types, low-lying areas prone to waterlogging).

- Map the location of each sensor node and the required Pisphere units. The density will depend on the power requirements of the chosen sensor and the local soil conditions.

Step 2: Pisphere Unit Installation:

- The Pisphere unit is typically buried near the plant’s root zone. This is often done during planting or a routine maintenance cycle.

- A small trench or hole is dug to accommodate the anode and cathode components, ensuring the anode is deep enough to be in the anoxic zone and close to the roots.

- The system is designed to be robust and withstand the pressure and vibration of typical farm machinery passing overhead.

Step 3: Sensor Node Connection:

- The sensor node, which houses the LPWAN radio and the sensing elements, is connected directly to the Pisphere unit’s output terminals.

- The node is then secured, often on a small stake or post, to ensure the antenna has a clear line of sight for data transmission.

Step 4: Network Integration:

- The sensor data is transmitted wirelessly to a central gateway (e.g., a LoRaWAN gateway) which is typically powered by a small, dedicated solar panel or grid connection.

- From the gateway, the data is sent to the farmer’s cloud-based farm management system for analysis and visualization.

By integrating Pisphere, the farmer creates a truly autonomous, self-sustaining data collection layer. The plants themselves become the power grid, turning a biological process into a digital asset.

IV. Economic and Environmental Impact: Beyond the Battery

The adoption of Pisphere technology in agriculture delivers a dual benefit: a powerful economic return on investment and a significant leap forward in environmental stewardship. This combination is crucial for modern farming, which is increasingly scrutinized for its sustainability practices.

The Financial Case for Pisphere

The initial cost of any new technology is a hurdle, but Pisphere’s long-term operational savings quickly make it a compelling investment.

Cost Comparison: Pisphere vs. Traditional Power (Per Sensor Node, 5-Year Lifecycle)

| Cost Factor | Pisphere (Plant-MFC) | Solar + Battery | Standard Battery (Replacement) |

|---|---|---|---|

| Initial Hardware | Moderate (MFC unit, small buffer) | High (Panel, large battery, charge controller) | Low (Initial battery cost) |

| Energy Source Cost | Zero (Plant exudates) | Zero (Sunlight) | High (Cost of 5-10 replacement batteries) |

| Maintenance/Labor | Very Low ($10-15/year for check-up) | High (Cleaning, battery replacement, panel repair) | Very High (Labor for 5-10 field visits per node) |

| Downtime Risk | Low (24/7 power) | Moderate (Cloudy days, night) | High (Battery failure, missed replacement) |

| Total 5-Year TCO | Lowest | Moderate to High | Highest |

The most dramatic saving comes from the elimination of labor costs associated with battery maintenance. For a farm with 5,000 sensors, replacing batteries twice a year means 10,000 field visits over five years. Pisphere reduces this to near zero, freeing up farm personnel for higher-value tasks.

Furthermore, the reliability of Pisphere translates directly into economic gains. Continuous, accurate data prevents costly mistakes like over-irrigation (wasting water and energy) or under-fertilization (reducing yield). Pisphere ensures the data stream is never interrupted by a dead battery, guaranteeing the integrity of the precision agriculture system.

A True Carbon-Neutral Solution

The environmental benefits of Pisphere align perfectly with the global push for sustainable and carbon-neutral farming practices.

- Elimination of Battery Waste: By replacing chemical batteries, Pisphere removes a significant source of toxic waste from the agricultural supply chain. Lithium, lead, and other heavy metals from batteries pose a serious environmental risk if not disposed of properly.

- Carbon Sequestration: The Pisphere system is inherently carbon-negative or carbon-neutral. It relies on the plant’s natural process of photosynthesis, which draws CO2 from the atmosphere. The energy generation process itself is a closed-loop system that utilizes the plant’s waste products.

- Reduced Energy Footprint: By powering sensors with bio-electricity, the farm reduces its reliance on grid power or fossil fuels for remote monitoring. This contributes to a lower overall energy footprint for the entire operation.

The technology allows farmers to not only meet but exceed the environmental, social, and governance (ESG) standards increasingly demanded by consumers and regulators. Pisphere is not just a power source; it is a statement of commitment to a truly sustainable future for food production.

V. Advanced Integration and Future Potential

While Pisphere’s immediate application is in powering simple sensor nodes, its potential extends far beyond basic monitoring. The technology is a foundational element for the next generation of autonomous and self-optimizing farms.

Hybrid Power Architectures

For applications requiring higher power bursts—such as activating a small solenoid valve for localized nutrient delivery or running a high-definition camera for a short period—Pisphere can be integrated into a hybrid power architecture.

In this setup, Pisphere serves as the baseline power generator, continuously charging a larger, more robust capacitor or a small, long-life battery. A small, high-efficiency solar cell might be added to the system to provide a supplementary charge during peak daylight hours. This hybrid approach maximizes reliability while minimizing the size and cost of the solar component and the frequency of battery replacement. The Pisphere unit ensures that the system never fully discharges, extending the life of all components.

Data-Driven Soil Health Management

The continuous, uninterrupted data stream provided by Pisphere-powered sensors enables a deeper understanding of soil health than ever before. Farmers can move beyond simple moisture readings to complex soil respiration monitoring.

By powering sensors that measure the CO2 flux from the soil, Pisphere helps quantify the microbial activity and organic matter decomposition rates. This data is a direct indicator of soil fertility and carbon sequestration potential. This level of granular, real-time data allows for:

- Adaptive Tillage: Adjusting tillage practices based on measured soil compaction and microbial health.

- Bio-Stimulant Optimization: Precisely timing the application of bio-stimulants to maximize microbial activity and nutrient cycling.

- Carbon Credit Verification: Providing verifiable, continuous data on the soil’s ability to sequester carbon, opening up new revenue streams through carbon credit markets.

The Future: Powering Autonomous Robotics

The ultimate vision for the unplugged farm involves autonomous, small-scale robotics. While Pisphere’s current output is designed for low-power sensors, the scalability of the Plant-MFC concept suggests a future where larger arrays of Pisphere units could power small, slow-moving robotic platforms.

Imagine a tiny, autonomous weeding robot that patrols a row of crops. It doesn’t need a massive battery; it needs a continuous, low-level charge to keep its navigation systems active and its motors ready for short bursts of work. A network of high-output Pisphere units embedded along the crop rows could potentially provide the necessary charging points or even a continuous power source for these micro-robots.

This future is not science fiction. It is the logical extension of a technology that recognizes the plant as a power station. Pisphere is the key to unlocking the full potential of hyper-precision agriculture, transforming the farm from a resource consumer into a self-sustaining, data-generating ecosystem.

VI. Implementation Guide: Making the Switch

Transitioning to a Pisphere-powered sensor network is a strategic decision that requires careful planning. This final section provides a practical guide for farmers ready to embrace this sustainable power solution.

Pilot Program and Scalability

The best approach is to start with a pilot program. Select a representative 10-hectare section of the farm that exhibits typical soil variability and crop types.

- Baseline Data Collection: Before installation, collect baseline data on soil moisture, pH, and yield in the pilot area using traditional methods.

- Phased Deployment: Install Pisphere units and sensor nodes in a phased manner. Start with a low density (e.g., 1 sensor per hectare) and gradually increase the density as you gain confidence in the system’s reliability and data quality.

- Comparative Analysis: For the first year, run a comparative analysis. Compare the cost of maintaining the Pisphere-powered sensors versus a control group of battery-powered sensors. Track labor hours, battery costs, and sensor downtime.

Overcoming Initial Challenges

While Pisphere is robust, there are initial considerations for optimal performance:

- Soil Type: Power output can vary based on soil composition and microbial diversity. Loamy soils with high organic content typically perform better than sandy or clay-heavy soils. A soil analysis can help predict performance.

- Plant Health: The system relies on healthy root exudates. Maintaining optimal plant health is crucial, which conveniently aligns with the farmer’s primary goal.

- Data Transmission: Ensure your chosen LPWAN technology (LoRaWAN, etc.) has adequate coverage across the entire farm. Pisphere powers the sensor, but a reliable gateway is still necessary to get the data to the cloud.

The Long-Term Vision

The investment in Pisphere is an investment in the farm’s future resilience. It is a hedge against rising energy costs, tightening environmental regulations, and the increasing demand for sustainably sourced food. By integrating this bio-power technology, farmers are not just installing a new device; they are fundamentally redesigning their farm’s infrastructure to be self-sufficient, data-rich, and ecologically sound.

The unplugged farm is no longer a distant dream. With Pisphere, the power to monitor, optimize, and sustain the next generation of agriculture is literally rooted in the ground.